Koa’s Community Mobile Pressing Units – Using the Power of Solar Energy and Technology to Overcome Infrastructural Barriers and Upcycle cocoa

What is the Innovation?

The Community Mobile Pressing Unit (“CMPU”) is a solar energy powered mini processing plant on wheels that combines hydro presses, sensor-controlled cooling and quality checks to create high value cocoa by-products for the food and beverage industry. The CMPU can process up to 1.2 tons of cocoa juice per hour – it extracts, filters and cools the traditionally unused pulp and juice. The design of the CMPU makes it possible to reach and directly engage with farmers in remote areas. Moreover, the CMPU keeps beans from different batches separated and allows farmers to follow the entire process through a large window.

Key Challenges Addressed

Approximately 77% of cocoa in West Africa is produced by smallholder farmers, many of whom live in poverty. Low cocoa prices and the increasing impact from climate change on cocoa quality and yield are further impacting smallholder income and livelihoods. Moreover, approximately ~75% of cocoa fruits go to waste, as traditionally only the cocoa beans are considered a source of income. Although the value of the pulp and juice (~17% of cocoa fruit) is known, industry players have shied away from pulp extraction due to its perishability, the lack of existing technology and infrastructure fit for extracting, pasteurizing, cooling and storing the pulp and juice, and the remoteness of farmers. The lack of infrastructure and remoteness of farmers also complicates closer farmer engagement, limiting transparency and traceability. Using the power of solar energy, the CMPU provides a possibility to overcome the infrastructural challenges and optimise the cocoa value chain, improving the value of the cocoa fruit and the livelihoods of smallholder cocoa farmers.

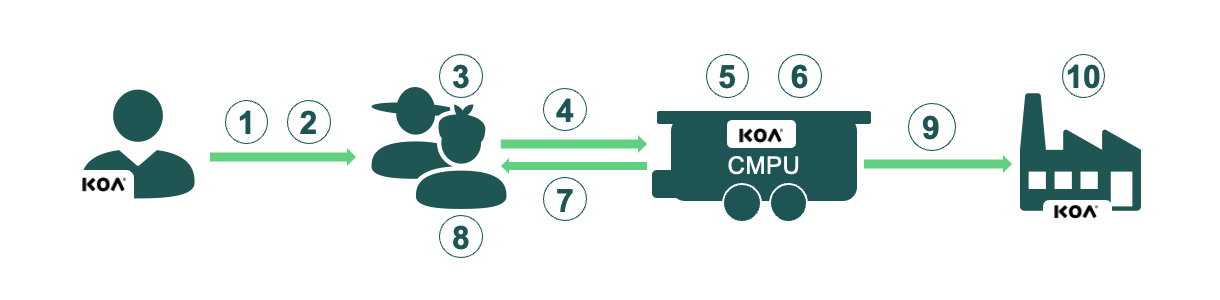

How it Works

- Koa employees train farmers how to open the pods and scoop out the beans in line with hygiene standards

- Koa employees contact farmers ahead of factory production days to coordinate the harvesting

- After harvesting, farmers open the pods and scoop out the beans at the farm, using the hygiene material (e.g. gloves, hairnets) and clean 15kg collection buckets provided by Koa

- Koa transports farmers with their full buckets to the nearest processing site*

- At the processing site, the farmer and a Koa employee count the number of buckets and register it on a big board. Afterwards, the data is put into an offline system that connects to the traceability blockchain platform as soon as it connects to the internet

- Koa extracts the pulp from the beans, returns the beans to the farmer and pays the farmer on the spot

- Koa transports the farmers and their cocoa beans to their farm community

- Farmers ferment, dry and package the cocoa beans, and sell them via local marketing centres to Licensed Buying Companies***

- The cooled juice is transported to Koa’s processing factory

- The juice undergoes extra checks to ensure the quality has not degraded during transportation and is then pasteurized, cooled and stored awaiting shipment to customers

* Pulp needs to be extracted within limited hours after opening the pod to avoid fermentation. Harvest from farms close to the factory is therefore transported directly to the factory; **Extraction happens both at CMPUs and at the factory; *** This whole process lasts ~2-3weeks

Tips for Replication

Context

- Farmers live in remote areas with underdeveloped infrastructure and lack access to (reliable) energy

- The full value of the (cocoa) crop is not being realized, presenting an opportunity to upcycle waste

Best practices

- Utilise local knowledge – involve farmers and employ locals from the community to tap into their local knowledge and understand their needs for the development of quality upcycle solutions

- Engage farmers and create trust through demonstration and explanation of the process and timelines, providing visibility of the crop’s journey throughout the process

- Focus on continuous learning, R&D and innovation to improve the processing of the crop and develop new consumer products.

- Provide farmers with complementary training on e.g. Good Agricultural Practices (“GAPs”), use of personal protective equipment, hygiene standards and Koa’s child labour standards to enhance climate resilience and crop quality and supply

- Utilise available digital solutions, such as blockchain, cloud-based infrastructure and mobile money, to provide supporting services that add value to the core product(s). E.g. the use of the transparency blockchain platform improves credibility and creates access to premium markets

- Minimise farmer participation barriers by facilitating easier access. E.g. provide free transport and facilitate registration to the mobile payment solution

Enabling Conditions

- Local communities and traditional authorities are supportive of the organization, embracing local job creation

- The increasing consumer demand aligns with the organisation’s product offerings

Business Case

(Expected) Outcomes for KOA

New revenue stream through upcycling

The extracted cocoa pulp is a new way to earn revenue from cocoa. The versatile ingredient has a natural flavour and sweetness that makes it interesting for the food and drink sector, especially for chocolate and confectionary producers. Amongst Koa’s customers are brands like Lindt and Valrhona who launched innovative products around the cocoa fruit.

Top Quality products

Koa’s decentralised pulp processing approach facilitates proximity to farmers which allows for strict quality and hygiene control measures. It also addresses the perishability challenge, enabling mild pasteurization that preserves the natural flavour, unlike competitors who must rely on ultra-high temperature processing.

100% Traceability

Direct engagement with farmers, instead of reliance on a network of intermediaries and agents like its competitors, enables Koa to register individual farmers and monitor their crop on its blockchain traceability platform. Exclusive use of mobile money payments also facilitates tracing products and additional income back to every single farmer.

Reduced carbon footprint

Chocolate has one of the highest carbon footprints in the food industry, mainly caused by food loss (~25%) and land use & farm activities (~70%) ². By upcycling the value of the cocoa fruit and using sustainable energy sources, the carbon footprint of cocoa cultivation within Koa’s supply chain can be reduced.

Impact Case

(Expected) Outcomes for smallholder farmers

Additional farmer income

After the pulp extraction, farmers receive their beans back, plus payment for the pulp. As the pulping process doesn’t affect the quality of the beans, farmers can still sell their cocoa beans. Depending on the # of buckets pulp supplied to Koa, farmers can earn up to 19%³ additional income from cocoa pulp without having to invest in any new tools, inputs or equipment.

Improved liquidity

Koa pays farmers on the spot at a point in time where farmers are typically cash-strapped – they have incurred costs for harvesting while having to wait at least a few weeks before receiving payment for their cocoa beans. On the spot payment for the pulp enables farmers to pay their harvest labour quickly and retain the future income from bean sales for themselves. It also improves farmer’s ability to hire labour, reducing the need to rely on (underaged) family members.

Increased financial security

By using the mobile money infrastructure, payments can be tracked which ensures the money reaches the rightful farmer, reducing the risk of theft and corruption. As payments are automatically registered, this also improves future access to financial services for unbanked farmers.

Enhanced post-harvest process

Free transport from the farm (via the processing site) to their farm community means farmers don’t have to arrange and pay for transport from their farms to the farm community, reducing costs and increasing efficiency. As at the farm, carrying the beans from the field to the house typically is an activity where children are involved, arranging free transport from the farm to the processing sight also mitigates the risk of child labour. Moreover, research⁴ shows that reducing liquid material around the beans shortens fermentation and lowers mould risk. Removing pulp and beans from farms prevents soil contamination by the acidic pulp juice.

Outstanding Risks & Challenges

- Koa experiences the effects of general cocoa sector challenges such as dependence of crop yield on rainfall, climate change awareness gaps among farmers, and competition with (illegal) mining. To reduce the impact of these challenges, Koa provides training on climate resilience and chooses its operation sites based on the absence of mining activities.

- The Ghana Cocoa Board (“COCOBOD”) controls cocoa marketing and exports in Ghana, resulting in dependence on this governmental institution. Recent liquidity issues of COCOBOD have delayed payments for cocoa beans and resulted in irregular distribution of governmental input support. Going forward this is expected to remain a challenge.

- Due to poor road quality, and to avoid fermentation and degradation, farms need to be within acceptable distance to the CMPU and the factory.

- Initial trust amongst farmers tends to be low because of unfamiliarity with Koa, which was exacerbated by doubtful behaviour of other actors in the cocoa value chain that claimed to work with Koa. Typically, farmers therefore supply a small amount of their harvest the first time they engage with Koa. To increase farmer trust and increase its sourcing volumes quicker, Koa has increased its farmer engagement activities.

- Koa’s factories run about 8-9 months per year and can only extract cocoa pulp and juice during day-light hours, meaning the factories are currently not fully utilised. As a solution, Koa is investigating the possibilities to process other fruits with harvest season counter-cyclical to cocoa.

- Of farmers onboarded, Koa doesn’t know who is going to supply how much cocoa and when, which is why Koa serves farmers on a first-come-first-serve basis. This sometimes results in farmers having to wait very long before their produce can be picked up.

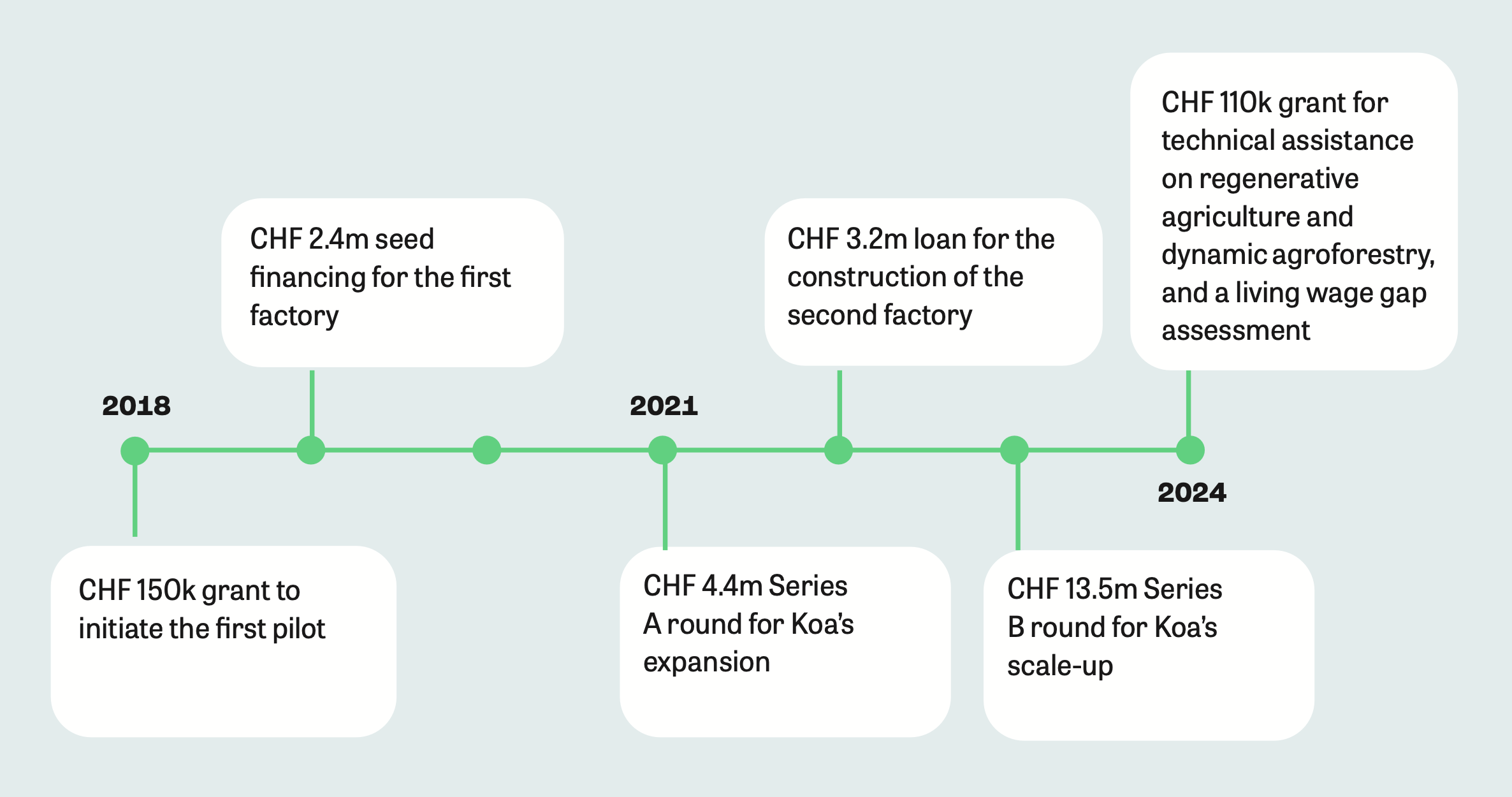

The Role of Finance Providers

After an initial investment from its founders, Koa has been able to attract financing from several impact and development focused finance providers⁵ (“FP”) for the development of its products and expansion of its business (see timeline).

Financing received by KOA

IDH Farmfit Fund ("Fund")

What: Senior secured term loan, CHF 1.2m (2022)

Purpose: Capex investments, for the establishment of a second production plant

Co-investor: Landscape Resilience Fund (“LRF”), CHF 2m

Rational: To further expand and scale Koa’s operations and increase its smallholder farmer outreach and raise their income. The Fund also recognised the potential of creating gender equal employment opportunities in rural communities and the possible spill-over effect of Koa’s approach to waste to other players in the food and beverage industry

Additionality: Because Koa was early stage, other investors were unable to finance the company with long-term debt suitable for the plant construction. Moreover, the Landscape Resilience Fund couldn’t provide the full financing needed.

(Expected) Impact of (Non-)Financial Support

Improved investability

At first, Koa was unable to attract financing from institutional investors as they considered Koa to be too small in terms of revenues and profitability. The financing provided to by impact investors helped Koa to bridge this gap and attract financing from an institutional investor in 2023. Support for the implementation of practices, such as an environmental and social management system, also helped to be perceived as more investment ready by institutional investors.

Increase farmer reach and impact

Financing for the creation of new sourcing regions and building additional factories and CMPUs enables Koa to increase its operations and farmer reach. It also facilitates Koa to continue improving its CMPU and the pulp extraction process, and to do R&D on other ways to upcycle the cocoa fruit, finding more ways to create additional income for farmers.

Strategic support

Koa’s business model and products are innovative and can create real additional value to the cocoa industry, both in terms of commercialisation and sustainability. In this context, Koa has experienced some benefits from investor connections with introductions to large cocoa and chocolate players for potential collaborations. Also, TA support to establish a regenerative agriculture and agroforestry pilot program, helps Koa strengthen farmer living income and climate resilience.

Construction 2nd processing plant

The investment by LRF and the Fund, for the construction and implementation of its second cocoa processing plant, allows Koa to:

- Increase its processing capacity from 300t to 3,000 tons over the next years

- Reach more farmers to increase supply and to impact livelihoods of more farmers – estimated to increase smallholder farmer reach to ~10.000 by 2026 of which 40% are female farmers.

- Reduce environmental footprint – everything in the processing plant follows Koa’s core idea that waste doesn’t exist, allowing for the recycling, upcycling and monetising of waste (e.g. water, packaging, etc.)

- Create new jobs – the new factory has already created 250 new jobs in rural areas with more to come during Koa’s continued ramp-up.

- Be trained on, and perform a gap assessment of the Living Wage concept and IDH Salary Matrix tool for the employees in the processing plant, facilitating improved employment conditions

Data Sources & Disclaimer

Information is based on data and documentation gathered by the IDH Farmfit Fund during the Investment Process (including Due Diligence) and Monitoring Calls and Visits. Additionally, interviews with farmers and company representatives have been held since the start of the first investment (2022). A longer time span and additional data are needed to verify and quantify impacts.

Footnotes:

- Koa Impact exists out of Koa Impact Ghana Ltd based in Accra, Ghana, with factory premises in Assin Akrofuom and Akim Achiase, Koa Switzerland AG based in Zurich, Switzerland, and Koa Germany GmbH based in Cologne, Germany. Koa Impact Ghana Ltd mainly focuses on farmer training and onboarding, factory operations and production of Koa products. More recently Koa Impact Ghana has also launched its first beverage on the Ghanaian consumer market. The European entities mainly focuses on the sales and distribution of Koa products outside of West Africa, as well as coordination of Business Development, R&D, Marketing and fundraising. The group works closely together on Logistics and Quality control.

- The study “Reducing food’s environmental impacts through producers and consumers” by Joseph Poore and Thomas Nemecek (2018) estimates the chocolate industry has 47kg CO2 emission per 1kg of food. For more info, also see the “Our World in Data” database

- Due to the volatile cocoa prices the % can vary quite a bit depending on when it is measured

- Research by the German Fraunhofer Institute

- Repic, various family offices, Haltra Group, responsAbility, Mirova’s LDN Fund, Landscape Resilience Fund & IDH Farmfit Fund

In this article

Your Insights Hub journey has just started

Sign up here for access to updates - and industry insights and innovation - from the Smallholder Inclusive Business Newsletter.